We use cookies to optimize our website and to provide you with the best experience. By continuing to browse this site you agree with our cookie policy

We have been supporting leading companies in the regulated environment for over 20 years.

We help you bring motivation, productivity, and quality to the next level.

We systematically get involved, we develop the people and the organization, and we do the implementation – with you and for you.

![]()

A good concept is an implemented concept that is paying off.

Our customers love our solutions because they are practical and because we work together to create them.

We won’t step away until the newly implemented approaches become a successful routine for you.

We build on smart digital applications that we adapt seamlessly to your work environment to boost your productivity.

We love to take our partners to the next level by playing with open cards and giving helpful feedback.

Do you appreciate a fresh perspective? We think entrepreneurially and challenge your approaches.

We're serious about having fun, because fun is how you get the most done.

How can your team achieve even more? How can your systems run even more productively? Together with your teams, we make processes more productive – in production, R&D, and labs. This is about success you can measure.

Ensure your launch is completed quickly and your products are manufactured as cost-effectively as possible with reliable supply chains. We help with the right processes and tools.

Mindset, processes, culture, leadership - you want to set up your entire system for the future? We help you identify the greatest potentials for improvement and achieve your objectives methodically and more systematically.

Smart tools used correctly often have an astounding effect on processes and teams. But what's the key? First lean the process, then digitize it. We provide support with our own web-based apps in combination with perfectly adapted commercially available software tools – a combination to trigger further improvements and transparency.

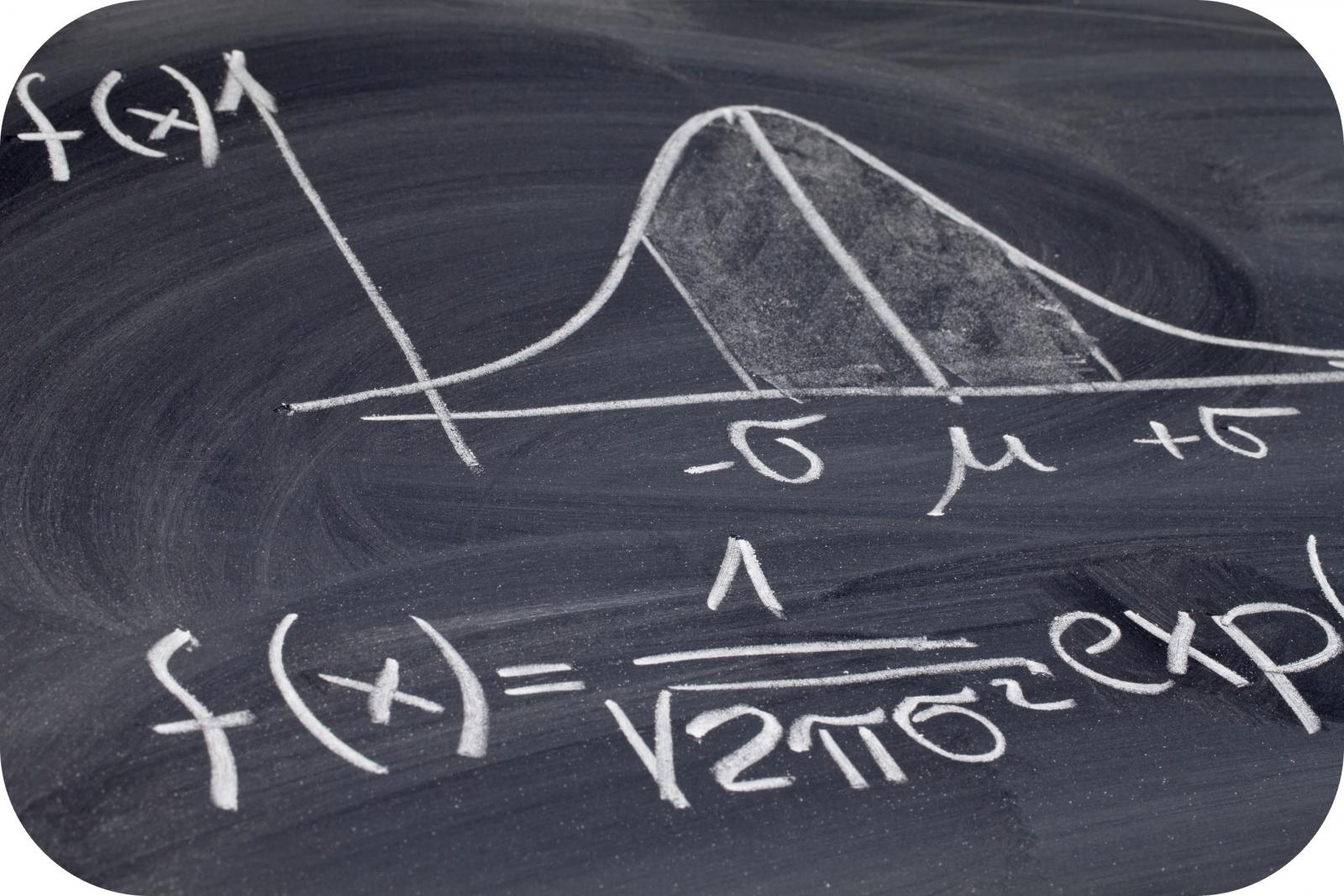

No matter whether it is about systematic root cause analysis, process validations, measurement system analysis, or statistical Design of Experiments: We provide in-depth expertise and a great deal of practical project experience in the field of applied statistics.

Expertise, experience, and passion for execution.

Success in implementation depends on your teams being fired up for new ways of working. Our projects are sustainably successful because we develop your internal competencies. We share a huge passion for seeing systems, organizations, and people grow.

Our specialization is the regulated environment, especially in the area of medical devices and pharmaceutical processes. Our customers are internationally active leading corporations as well as a broad range of medium-sized companies.

Acino Pharma · Bio-Rad· Black Forest Medical Group · BPL · Centrient · Grünenthal · Johnson & Johnson · Kemira · Lonza · Luye Pharma · MorphoSys · Nobel Biocare · Novartis · Rheinmetall· Rehau · Roche · Siemens · Stada · Stockert Medical Solutions · Stryker · Qiagen · Takeda · West Pharmaceutical Services